Top Industrial Flooring Installer Services Near You 2025 Trusted Guide

Searching for a reliable industrial flooring installer in 2025? You’re in the right place. Industrial flooring demands strength, precision, and endurance qualities only skilled contractors can deliver. Whether you’re managing a factory, data center, or logistics hub, your floors must handle heavy traffic, machinery, and chemical spills without cracking under pressure.

What Is an Industrial Flooring Installer?

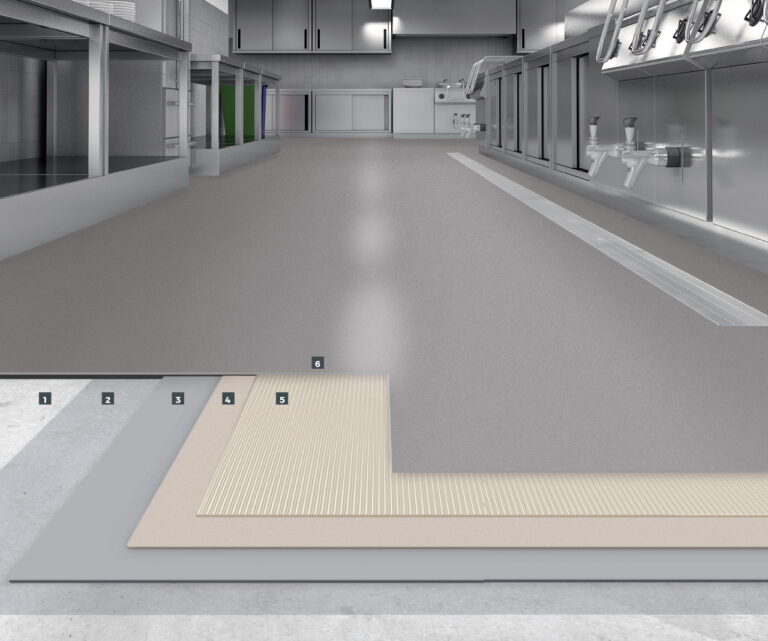

An industrial flooring installer specializes in laying high-performance coatings like epoxy, urethane, or polyurethane concrete systems. These professionals ensure the substrate is prepped correctly, materials are mixed and applied under exact conditions, and the finish meets safety and regulatory requirements.

Experienced installers often work with industries like:

- Manufacturing

- Warehousing

- Automotive

- Pharmaceuticals

- Cold storage

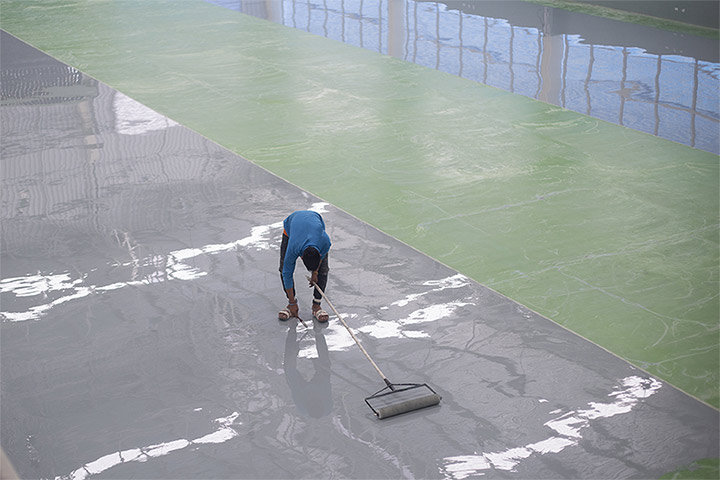

They handle surface prep (shot blasting or diamond grinding), apply primers, lay base coats, and finish with anti-slip or UV-stable topcoats.

Benefits of Hiring a Professional Industrial Flooring Installer

Proper Surface Prep and Installation

DIY or general contractors often miss key steps. A qualified industrial flooring installer ensures full adhesion and prevents peeling or bubbling, extending floor life by years.

Compliance and Durability

Installers ensure floors meet OSHA, FDA, or cleanroom standards where required. They also offer warranties, ensuring peace of mind.

Customization and Functionality

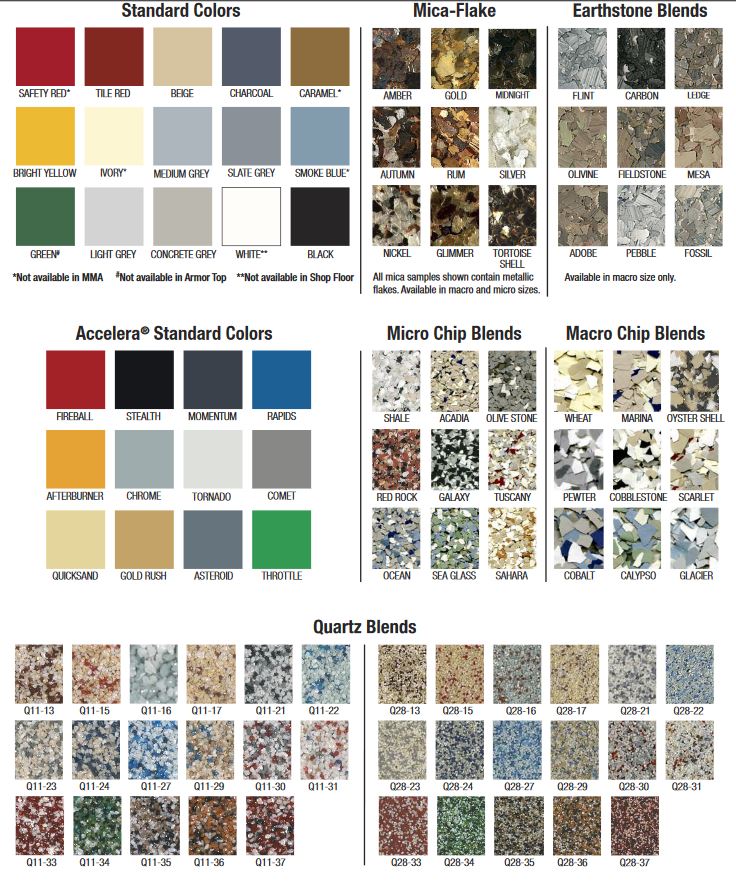

Need anti-slip safety zones? Chemical resistance? Color-coded work areas? A good installer can tailor your system to suit your facility’s needs.

Popular Types of Industrial Flooring Systems

Epoxy Flooring

Great for general industrial use. It’s durable, affordable, and offers a clean, professional finish.

Polyurethane Cement Flooring

Ideal for wet or cold environments. It’s resistant to thermal shock, making it perfect for food processing or freezer rooms.

Methyl Methacrylate (MMA) Systems

These rapid-cure floors are ready in hours, minimizing downtime, ideal for retail and 24/7 operations.

Top 5 Industrial Flooring Products in 2025

Flowcrete Flowfresh HF

Flowfresh HF resin flooring is applied in a food-grade facility. A heavy-duty polyurethane floor offering anti-microbial protection. Ideal for food and beverage plants.

Sikafloor-264

Sikafloor epoxy system in a warehouse.e A high-performance epoxy resin floor used in commercial and light-industrial spaces. UV stable and seamless.

ArmorPoxy Ultra Industrial System

Armorpoxy is applied in the logistics center. Known for extreme chemical resistance and long wear cycles, perfect for auto repair shops and aviation hangars.

Resdev Pumadur HF

Pumadur HF resin flooring for chemical industries. A resin-rich screed system for heavy-duty use. Used in pharmaceuticals and chemical production.

Dur-A-Flex Hybri-Flex EC

Hybri-Flex EC resin system in the factory combines epoxy and cementitious urethane for high-strength flooring. Great for mixed-use industrial areas.

Use Cases: Why Facilities Need Industrial Installers

- Warehouses: Combat tire marks, wear, and cracking.

- Food plants: Prevent bacterial buildup with seamless flooring.

- Pharmaceuticals: Ensure sterile environments.

- Cold Storage: Flooring that won’t shatter in freezing temps.

Industrial facilities deal with specific challenges like forklift traffic, exposure to corrosive agents, and fluctuating temperatures. The right floor installer provides solutions that handle all of these issues long-term.

Where to Buy Industrial Flooring Systems

You can purchase the above products online via official websites:

Buy Flowfresh HF

Buy Sikafloor-264

Always check with your installer to confirm compatibility and preferred brands.

FAQs

How long does industrial floor installation take?

Depending on system type and facility size, expect 2 to 7 days, including prep and cure time.

What’s the lifespan of industrial flooring?

Epoxy and urethane systems can last 10–20 years with proper care.

Can I install these floors myself?

DIY epoxy kits are available, but not suitable for industrial use. Hiring professionals ensures safety and durability.

Conclusion

An expert industrial flooring installer is essential for reliable, high-performing floors in 2025. Whether you’re renovating a warehouse or building a new production facility, the right contractor ensures your floors meet performance, safety, and compliance standards. Use this guide to explore the best products, understand your options, and confidently invest in long-term flooring solutions.